Shrinkage - changes in the size of the material after wet processing.

Any fabric after washing tends to shrink in size or, in other words, shrink. Some fabrics do this to a greater extent, others to a lesser extent. It all depends on the composition of the fiber from which the fabric is woven. The materials that are most susceptible to shrinkage are those that are able to absorb more moisture, and these, in turn, are those that contain natural fibers-cotton, linen, artificial (viscose, etc.).

An important point is the production method itself (weaving, knitting), as well as its subsequent temperature treatment during the production process, which allows you to reduce the shrinkability of the fabric after getting wet.

For example, when weaving calico and satin, various methods of weaving threads are used, which also affects the shrinkage. Calico is more susceptible to shrinkage than satin.

If we consider a synthetic material that consists of 100 % polymer fiber, which does not provide moisture absorption, then it is less susceptible to shrinkage. Synthetic fabric, on the contrary, has the property of increased stretchability.

In order to understand the very essence of shrinkage, we will conduct an experiment. Let's take two sheets-one paper (based on a natural material-wood), the other polyethylene (made of polymer). We'll wet them and see what happens to them after they dry. So, the paper sheet is deformed and slightly reduced in size, and the plastic sheet will not change its original shape.

In order to minimize the shrinkage of the fabric during their production, various chemical additives and stabilizers are often used.

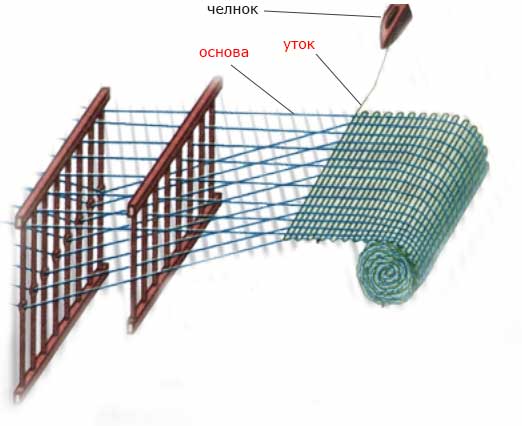

It should also be noted that shrinkage can occur both on the weft and on the base of the web.

And what is the base and weft of the fabric?

The thread that runs along the web when it is made is called the base, and the one that runs across it is called the weft. This is the technology of weaving.

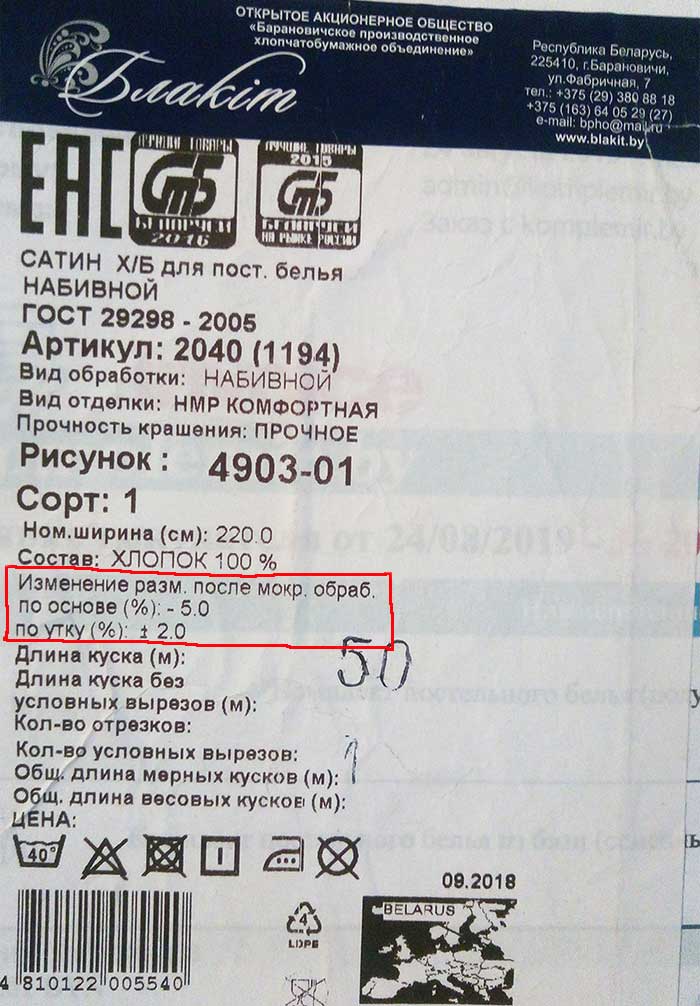

Therefore, in the production of fabric, its passport indicates not just shrinkage as a whole, but divides it by the value of the base and the weft separately.

To make it clear how the material can "sit down" after washing, we will analyze a specific example in accordance with the stated requirements of the fabric manufacturer.

From the data on the fabric, it can be seen that the size change after wet treatment on the base is -5 %, on the weft +/- 2%. That is, if you wash a piece of fabric measuring 100 cm in width and 200 cm in length, then it can sit down as much as possible in width (duck) up to 98 cm, and in length (base) up to 190 cm.I would also like to note that these shrinkage values are characteristic only under the correct washing conditions of this material. In other cases, even greater deviations are possible. That is, if, for example, when washing powders with special additives are added, an air conditioner and a centrifuge with increased spin speeds are used.

Thus, when sewing any sewing products from cotton fabric, be it bed linen, dress, kitchen apron, etc., it is necessary to take into account its shrinkage after washing.

+375 29 34 37 358

+375 29 34 37 358 +375 33 34 37 368

+375 33 34 37 368

!

! !

!